Spark Stabilized Soil Mixing Plant

Stabilized soil mixing plant is a kind of equipment used to produce stabilized soil mixture, which is widely used in infrastructure construction such as road construction, airport runways, port terminals, etc. Stabilized soil mixture is usually made of soil, stabilizer (such as cement, lime, fly ash, etc.) and water. After mixing, paving and compaction, it forms a solid base layer or pavement base.

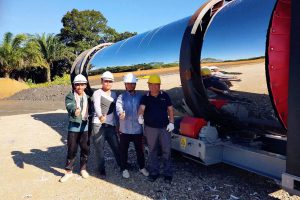

The stabilized soil mixing stations produced by our factory are mainly divided into two types, fixed stabilized soil mixing stations and mobile stabilized soil mixing stations. Both types of equipment can be used to produce stabilized soil mixtures.

Types of spark Stabilized Soil Mixing Plant for sale

Stabilized soil mixing plant is a collection of mechanical equipment used to produce stabilized soil. It is mainly used to mix cement, lime, fly ash and other binders with soil, gravel or other aggregates to make stabilized soil. This equipment is widely used in the base construction of infrastructure such as high-grade highways, urban roads, squares, airports, etc.

Applies to:

Highways and urban roads: used for base and subbase construction.

Airports and squares: used for laying stabilized soil layers.

Sports fields and parking lots: provide a solid foundation layer

What is a Stabilized Soil Mixing Plant?

Stabilized soil mixing plant is an indispensable equipment in modern infrastructure construction. Its efficient and reliable performance provides solid support for various large-scale projects. Choose the stabilized soil mixing plant produced by Spark to achieve efficient production of stabilized soil and provide reliable material guarantee for infrastructure construction.

Stabilized soil mixing plants usually consist of the following main parts:

Mixing system: core component, usually using a twin-shaft continuous forced mixer.

Control system: used to monitor and adjust the entire production process.

Batching system: including aggregate silo and powder distribution system.

Conveying system: used to convey the mixed material to the mixer.

Storage system: used to store the mixed finished material.

Cement tank: used to store cement and other binders

batching machine

Mixing system

Control system

Cement tank

Use a loader to load the aggregates required for the project into each hopper, open the discharge door, and then open the discharge belt, and the horizontal belt conveyor will send the aggregates into the mixing device. The mixing water is pumped to the water adder nozzle through the regulating valve and pipeline according to the amount of water required for the project, and evenly sprayed in the mixing device. The propeller blades stir the materials to form a uniform material. The mixed materials fall from the discharge port onto the belt conveyor, and are transported to the storage bin by the belt conveyor, waiting for the material transport truck to load the materials.

Stationary Stabilized Soil Mixing Plant for sale

The stationary stabilized soil mixing plant is a special equipment used to produce stabilized soil. With its efficient and reliable performance, it provides solid support for infrastructure construction and is an indispensable equipment in modern engineering construction.

Model: WBZ300、WBZ400、WBZ500、WBZ600、WBZ700、WBZ800

Capacity: 300-800T/h

Power: 88-200kw

Fixed installation: requires pre-cast concrete foundation, not easy to move after installation, suitable for long-term, large-scale construction projects.

High production capacity: usually has a high production capacity, can meet the needs of large-scale construction.

High degree of automation: equipped with advanced control system, can achieve automated operation and precise control of the production process.

Strong structure: made of high-quality steel and wear-resistant materials, with a long service life and good stability.

advantages of Stationary Stabilized Soil Mixing Plant

1.Efficient production: The fixed design and high production capacity can meet the needs of large-scale construction.

2.Precise control: The advanced control system ensures the accuracy of batching and mixing, and improves the quality of stabilized soil.

3.Strong durability: The use of high-quality materials and wear-resistant parts has a long service life of the equipment and low maintenance costs.

4.Reasonable layout: The machine adopts an overall functional design, which is easy to install, easy to move, moderate working station, uniform mixing and high efficiency.

5.Convenient installation: The machine does not require a special foundation for installation, only a piece of land needs to be compacted, and the equipment investment and production costs are low.

Parameters of Stationary Stabilized Soil Mixing Plant

| Model | WBZ300 | WBZ400 | WBZ500 | WBZ600 | WBZ700 | WBZ800 |

| Productivity (t/h) | 300 | 400 | 500 | 600 | 700 | 800 |

| Total Power (kw) | 88 | 105 | 158 | 168 | 179 | 200 |

| Total Weight (t) | 39 | 41 | 50 | 54 | 63 | 72 |

| Measuring Mode | Computer Measuring | |||||

| Speed Regulation Mode | Frequency Control | |||||

| Control Mode | Semi-auto/Full-auto Mode | |||||

| Max. Aggregate Size (mm) | 60 | |||||

| Aggregate Measuring Accuracy (%) | ±2 | |||||

| Powder Measuring Accuracy (%) | ±1 | |||||

| Water Measuring Accuracy (%) | ±1 | |||||

If the above parameters do not meet your production needs, you can contact us to let us know your specific requirements and we will design a unique solution and quotation for you.

Mobile Stabilized Soil Mixing Plant for sale

The mobile stabilized soil mixing plant is a flexible and efficient construction equipment. Compared with the fixed mixing plant, the mobile mixing plant has higher mobility and flexibility, and is suitable for small and medium-sized construction or projects that require frequent transfers.

Model: YWBZ200、YWBZ300、YWBZ400、YWBZ500

Capacity: 200-500t/h

Power: 60-120kw

High mobility: Designed to be mobile, it integrates mixing, batching, and conveying systems, and can be quickly disassembled and transferred. Suitable for construction sites that require frequent movement, such as road maintenance, temporary construction, etc.

Compact structure: Suitable for use at construction sites with limited space.

High degree of automation: Equipped with advanced control systems, it can achieve automated operation and precise control of the production process. It can switch between manual and automatic operation modes.

Efficient production: Although the production capacity is relatively low compared to fixed mixing plants, it is sufficient to meet the needs of small and medium-sized construction. High production efficiency and the ability to quickly complete construction tasks.

advantages of Mobile Stabilized Soil Mixing Plant

1.Flexible and maneuverable: easy to disassemble and transport, can be quickly transferred, suitable for construction sites that need to be frequently moved.

2.Small footprint, suitable for use in sites with limited space, no complicated operation required.

3.Efficient production: meet the needs of small and medium-sized construction, high production efficiency, and can quickly complete construction tasks.

4.High degree of automation: equipped with advanced control systems, it can achieve automated operation and precise control of the production process.

Parameters of Mobile Stabilized Soil Mixing Plant

| Model | YWBZ200 | YWBZ300 | YWBZ400 | YWBZ500 |

| Productivity (t/h) | 200 | 300 | 400 | 500 |

| Total Power (kw) | 60 | 80 | 100 | 120 |

| Mixer capacity (m³) | 2 | 3 | 4 | 5 |

| Measuring Mode | Computer Measuring | |||

| Speed Regulation Mode | Frequency Control | |||

| Control Mode | Semi-auto/Full-auto Mode | |||

| Max. Aggregate Size (mm) | 60 | |||

| Aggregate Measuring Accuracy (%) | ±2 | |||

| Powder Measuring Accuracy (%) | ±1 | |||

| Water Measuring Accuracy (%) | ±1 | |||

If the above parameters do not meet your production needs, you can contact us to let us know your specific requirements and we will design a unique solution and quotation for you.

Application Areas

The stabilized soil mixing line produced by our factory is suitable for the base construction of various construction projects, such as various small and medium-sized highways and urban roads, stabilized soil layers of airport runways and squares, temporary road maintenance, emergency construction, foundation paving of small parking lots and sports fields, etc.

Spark Stabilized Soil Mixing Plant Price List

| Types | Price range |

| Stationary stabilized soil mixing plant | $20,000-$150,000 |

| Mobile stabilized soil mixing plant | $15,000-$100,000 |

The price you pay depends on the line, machine and capacity you choose. The more equipment you choose and the greater the capacity, the higher the price you need to pay.

We also offer tailor-made solutions. If you are ready to start a project, please feel free to contact us for a customizable planning design and detailed price tag.