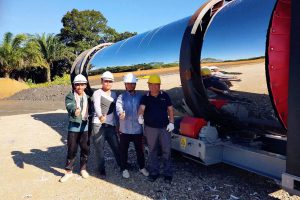

Spark Concrete Pump

A concrete pump is a mechanical device used to continuously transport concrete along a pipeline. It is widely used in large-scale projects such as buildings, bridges, and tunnels. Its main function is to transport concrete from a mixing plant to the construction site under pressure, thereby improving construction efficiency and project quality.

The concrete pumps produced by our factory mainly have three specifications, motor-driven concrete pumps, diesel-driven concrete pumps and brick foam pumps

Types of spark Concrete Pumps for sale

The concrete pumps produced by our factory can quickly transport large amounts of concrete, saving time and manpower. They are suitable for various complex terrains and construction environments. They adopt advanced hydraulic systems and wear-resistant materials, and have a longer service life.

Application scenarios:

High-rise buildings: used to transport concrete to the construction area of high-rise buildings.

Bridges and tunnels: provide concrete delivery solutions at construction sites that are difficult to reach.

Urban landscape construction: used for projects such as parks and squares that require complex terrain construction

What is a Concrete Pump?

A concrete pump is a mechanical device used to continuously transport concrete along a pipeline. Its main function is to transport concrete from a mixing plant to a construction site under pressure. It is an indispensable equipment in modern construction projects. Its high efficiency and reliability make it an important tool for improving construction efficiency and quality.

Concrete pumps are mainly composed of the following parts:

Pump body and delivery pipe: The pump body is responsible for sucking concrete and delivering it to the designated location through the delivery pipe.

Boom (arm): Used to deliver concrete to a higher or farther location, usually installed on the top of the pump truck.

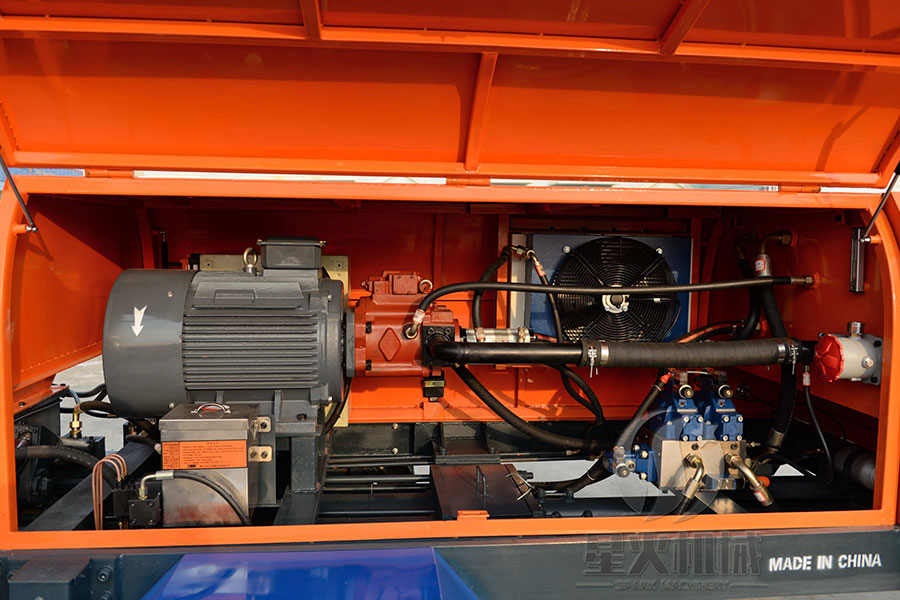

Power system: It can be an electric motor or a diesel engine, providing power to drive the pumping system.

pipeline

Power Source

Control system

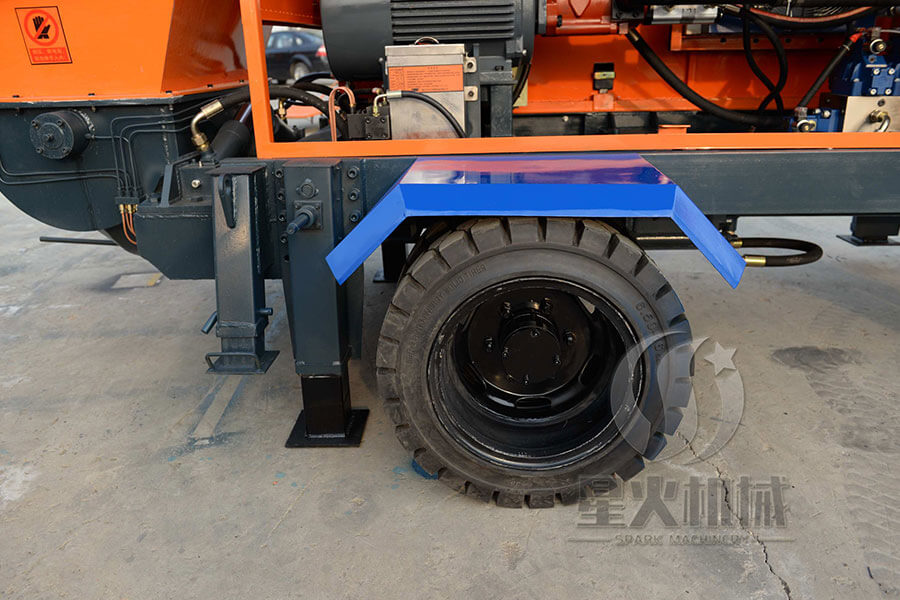

Mobile frame

The mixed concrete is unloaded into the concrete pump hopper, and the hydraulic system makes the hydraulic cylinder work. The hydraulic cylinder pushes the concrete pumping cylinder, one to suck material and the other to pump, and they work in a cycle in sequence to pump the concrete to a long or high distance.

Motor powered concrete pump for sale

Motor-powered concrete pump is an efficient and environmentally friendly concrete delivery equipment suitable for a variety of construction environments, especially in cities and projects with high environmental requirements. Its environmental performance and low maintenance cost make it an increasingly popular choice in modern construction projects.

Model: HBT40、HBT50、HBT60、HBT80、HBT90

Capacity: 40-90m³/h

Power: 45-110kw

The motor-powered concrete pump is a concrete conveying equipment that uses an electric motor as a power source and is widely used in construction.

Power source: The motor is used as the power source, driven by electricity, and provides stable power output. This power mode reduces dependence on fossil fuels.

Environmental performance: Low noise and low emissions during operation, in line with modern environmental protection requirements. Since no diesel engine is used, exhaust gas and wastewater emissions are avoided, which is particularly suitable for use in cities and areas with high environmental protection requirements.

Maintenance cost: The motor structure is relatively simple, and the maintenance and maintenance costs are low. There is no need to frequently replace the oil and filter element, which reduces the maintenance workload and reduces the long-term use cost.

Easy operation: The motor starts quickly and is easy to operate, which is suitable for frequent starting and stopping conditions. It has good speed regulation performance, and the conveying speed can be adjusted as needed to improve construction efficiency.

advantages of Motor powered concrete pump

1.Equipped with a control panel and a remote controller, it is easier to control remotely or manually.

2.Full hydraulic system, the machine runs stably during operation.

3.Equipped with two cooling systems for the whole machine and the power system.

4.Strong pumping capacity: can pump 120 meters in height and 300 meters in horizontal distance.

5.The control system uses Omron and Schneider Electric accessories, and American Sunny hydraulic hoses.

Parameters of Motor powered concrete pump

| Model | HBT40 | HBT50 | HBT60 | HBT80 | HBT90 |

| Max. theo. pump | 40m³/h | 50m³/h | 60m³/h | 80m³/h | 90m³/h |

| Hopper capacity | 600L | 600L | 600L | 600L | 800L |

| Motor power | 45kw | 55kw | 90kw | 110kw | 110kw |

| Hydraulic system | Open circuit | Open circuit | Open circuit | Open circuit | Open circuit |

| Pumping pressure | 10Mpa | 12Mpa | 13Mpa | 15Mpa | 18Mpa |

| Max. aggregate size | 20mm | 20mm | 30mm | 40mm | 50mm |

| Outlet diameter | 100mm | 100mm | 120mm | 120mm | 150mm |

| Machine weight | 3200kg | 3500kg | 5500kg | 5800kg | 6480kg |

If the above parameters do not meet your production needs, you can contact us to let us know your specific requirements and we will design a unique solution and quotation for you.

Diesel engine powered concrete pump for sale

The diesel powered concrete pump is a powerful and independent concrete delivery equipment suitable for various large-scale construction projects and construction in remote areas. Its strong power output and durability make it perform well in harsh construction environments.

Model: HBTS30、HBTS40、HBTS50、HBTS60、HBTS80

Capacity: 30-80m³/h

Power: 56-145kw

Power source: Diesel engines are used as the power source, which provide power by burning diesel, suitable for heavy loads and long-term continuous work.

Strong independence: It does not rely on external power supply and is suitable for use in remote areas or construction sites with unstable power supply.

Powerful: Diesel engines usually have high power and torque output, can provide strong power support, and are suitable for conveying large amounts of concrete or working in complex terrain conditions.

Durability: Diesel engines have a sturdy structure, are wear-resistant, and are suitable for long-term high-intensity work. Its durability enables it to perform well in harsh construction environments.

advantages of Diesel engine powered concrete pump

1.Strong power: Diesel engine is used as the power source, suitable for heavy load and long-term continuous work.

2.Strong independence: It does not rely on external power supply, suitable for remote areas or environments with unstable power supply.

3.High durability: The diesel engine has a strong structure and is wear-resistant, suitable for harsh construction environments.

4.Efficient hydraulic system: The hydraulic oil has high cleanliness, low oil temperature, and small switching impact.

5.Good sealing: The wearing parts are economical and durable, easy to replace, and there is no risk of oil leakage.

Parameters of Diesel engine powered concrete pump

| Item | HBTS30 | HBTS40 | HBTS50 | HBTS60 | HBTS80 |

| Max. theo. pump | 30m³/h | 40m³/h | 50m³/h | 60m³/h | 80m³/h |

| Hopper capacity | 400L | 400L | 400L | 800L | 800L |

| Engine power | 56kw | 62kw | 82kw | 129kw | 145kw |

| Hydraulic system | Open circuit | Open circuit | Open circuit | Open circuit | Open circuit |

| Pumping pressure | 26Mpa | 28Mpa | 32Mpa | 32Mpa | 32Mpa |

| Max. aggregate size | 20mm | 20mm | 30mm | 40mm | 50mm |

| Outlet diameter | 100mm | 100mm | 120mm | 120mm | 150mm |

| Machine weight | 3500kg | 4500kg | 4600kg | 4800kg | 6480kg |

If the above parameters do not meet your production needs, you can contact us to let us know your specific requirements and we will design a unique solution and quotation for you.

brick foam pump for sale

Foam concrete machine is a kind of middle one according our many years of working experience. It includes a screw feeder, a mixer, a set of foaming system and a foam concrete pump, adopts advanced control technology, can exactly adjust foam cement density.

Model: FP05、FP10、FP20

Concrete pouring volume: 5-20m³/h

Power: 11-53kw

Foam concrete pump is a mechanical device specially used to transport foam concrete. Foam concrete is a lightweight concrete that is made by introducing foam into the concrete to form a porous structure, thereby reducing the density and weight of the concrete. Foam concrete pumps are widely used in the fields of construction, insulation, foundation backfill, etc., especially in construction occasions that require lightweight materials.

The machine is mainly composed of chemical adding system, agitator, feeding screw conveyor, foam pump and other systems. The materials are put into the screw conveyor and then transported to the agitator. After mixing, they are transported to the material port. At the same time, the chemical agents also enter the conveying system. The mixed materials and chemical agents enter the pump and then flow into the brick mold to make foam bricks.

Foam concrete pumps are widely used in construction, insulation, foundation backfill and other fields, especially suitable for construction occasions that require lightweight materials. They are most commonly used in building exterior wall insulation, roof insulation, foundation backfill, filling and insulation layer construction of roads and bridges, and building structures that require sound insulation and earthquake resistance.

advantages of brick foam pump

1.The static mixer mixes the foam and mud, and the length of the conveying pipe can be adjusted according to requirements.

2.The main mixer can add raw materials, sand, mud, water and mix them evenly.

3.Double mixing system to ensure continuous production and uniform density.

4.The whole machine is centrally controlled, easy to operate and highly efficient.

5.The entire lightweight concrete foam machine adopts an automatic lubrication system.

6.The thickness of the main steel exceeds 6mm and has a long service life.

Parameters of brick foam pump

| The Foam Pump Model | FP05 | FP10 | FP20 |

| Max. theoretical concrete put | 5m³/h | 10m³/h | 20m³/h |

| Motor power | 11kw | 15kw | 53kw |

| Max.convening distance vertical | 40m | 40m | 80m |

| Max.convening distance horizontal | 300m | 300m | 500m |

| Mixing tank capacity | 200L | 350L | 580L |

| Filling height | 880mm | 1000mm | 1100mm |

| Overall dimension | 2100*1340*1390mm | 2850*1000*1500mm | 4000*1500*1900mm |

| Weight | 1580kg | 1700kg | 3000kg |

If the above parameters do not meet your production needs, you can contact us to let us know your specific requirements and we will design a unique solution and quotation for you.

Application Areas

Concrete pumps are widely used in high-rise building construction, bridge engineering, tunnel engineering, cement engineering, road and airport construction, civil building construction and other fields.

Spark concrete pump Price List

| Types | Price range |

| Motor powered concrete pump | $12,000-$30,000 |

| Diesel engine powered concrete pump | $15,000-$30,000 |

| Brick foam pump | $5,600-$10,000 |

The price you pay depends on the line, machine and capacity you choose. The more equipment you choose and the greater the capacity, the higher the price you need to pay.

We also offer tailor-made solutions. If you are preparing a concrete pump, feel free to contact us for a customizable planning design and detailed price tag.