Spark Concrete Auxiliary Equipment

The concrete auxiliary equipment produced by Henan Spark refers to the conveying and storage equipment used in the concrete batching station, which is the related machines used in the process of concrete production.

Common concrete auxiliary machinery produced by our factory include: aggregate batching machine, screw conveyor, cement silo, etc.

Types of spark Concrete auxiliary equipment for sale

As a manufacturer of construction concrete machinery and equipment, Henan Spark not only produces various production line equipment, but also various auxiliary equipment used in the production of concrete.

Concrete auxiliary equipment refers to various mechanical equipment used in the production, construction and maintenance of concrete. The main functions of these equipment are to improve production efficiency, ensure construction quality and ensure construction safety.

Batching machine: responsible for accurately measuring and mixing various raw materials (such as sand, stone, cement, water and admixtures) to ensure the quality and performance of concrete.

Screw conveyor: used to transport materials from one station to another to improve production efficiency.

Cement silo: used to store cement.

What is a Concrete auxiliary equipment ?

Concrete auxiliary machinery refers to mechanical equipment used to assist the main concrete machinery in the operation during the concrete production, construction and maintenance process. The main purpose of these equipment is to improve production efficiency, ensure construction quality and ensure construction safety.

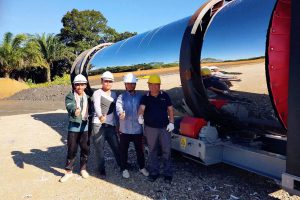

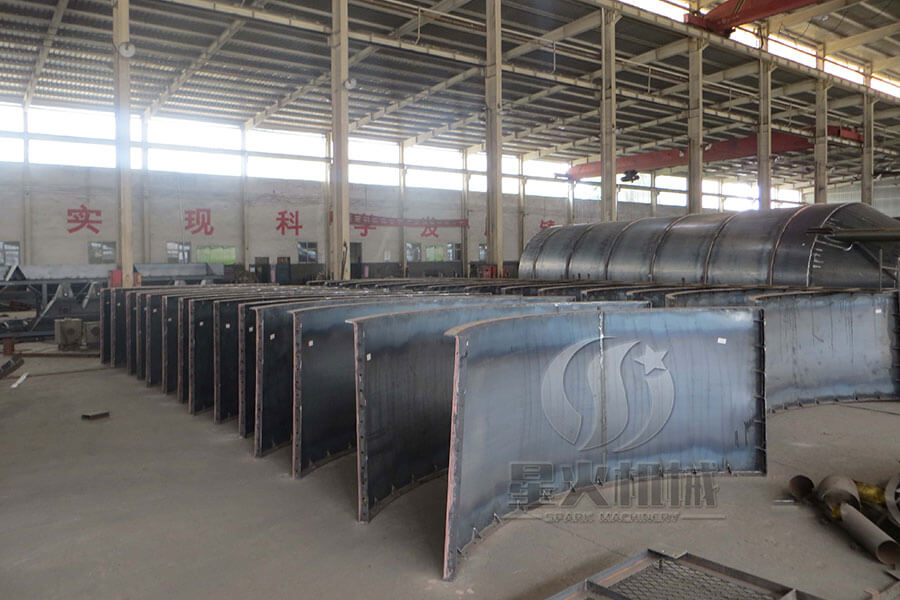

All auxiliary equipment used in the concrete batching plants produced by our factory are independently manufactured. The quality of all equipment is excellent, and the thickness and quality of steel are leading in the industry.

Concrete auxiliary equipment is an indispensable machine and equipment for concrete batching stations and other production lines in the process of producing concrete. High-quality concrete auxiliary equipment can provide long-term protection and support for concrete batching stations.

Aggregate batching machine for sale

Batching machine for concrete machinery transport stones, sand, stone and other raw materials, the raw material through the belt, said transported to the host, and cement to form concrete mixing. Applicable to general construction sites, roads, bridges and other projects.

Model: PLD800、PLD1200、PLD1600、PLD2400、PLD3200、PLD4800

Capacity:48-180m³/h

Power: 6.6-18.5kw

Concrete batching machine is an automated equipment used in concrete production, mainly used for accurate quantitative distribution of various materials (such as sand, stone, cement, etc.). It is an important part of the fully automatic concrete mixing station, which can effectively replace the traditional manual metering method and improve production efficiency and batching accuracy.

Quantitative distribution: The concrete batching machine can automatically distribute various materials to the mixer in proportion according to the set formula to ensure the quality and consistency of the concrete.

Automated operation: Through electronic weighing and microcomputer control, the batching machine can realize the automated batching process, reduce manual intervention and improve production efficiency.

Multi-material processing: The batching machine can process the batching of various materials, including sand, stone, cement, etc., and can even process additives such as admixtures.

advantages of Aggregate batching machinerete mixer

1.High efficiency: The automated batching process greatly improves production efficiency.

2.High precision: The electronic weighing system ensures high precision and consistency of batching.

3.Flexibility: The batching formula and proportion can be adjusted according to different engineering requirements.

4.Stability: The conveying is smooth, equipped with a material blocking cover, and there is no leakage.

Parameters of Aggregate batching machine

| Model | PLD800 | PLD1200 | PLD1600 | PLD2400 | PLD3200 | PLD4800 |

| Weighing bucket capacity | 800L | 1200L | 1600L | 4*2400L | 4*3200L | 4*4800L |

| Capacity of storage hopper | 2*2m³ | 2*3.5m³ | 2*5m³ | 4*15m³ | 4*18m³ | 4*23m³ |

| Theoretical productivity | 48m³/h | 56m³/h | 75m³/h | 120m³/h | 160m³/h | 180m³/h |

| Accuracy of batching | ±2% | ±2% | ±2% | ±2% | ±2% | ±2% |

| Max. Weighing | 2000kg | 3000kg | 3000kg | 4000kg | 5000kg | 8000kg |

| Belt conveyor speed | 1.25m/s | 1.25m/s | 1.4m/s | 1.25m/s | 1.4m/s | 1.25m/s |

| Power | 3*2.2kw | 3*3kw | 3*5.5kw | 11kw | 15kw | 18.5kw |

If the above parameters do not meet your production needs, you can contact us to let us know your specific requirements and we will design a unique solution and quotation for you.

Screw Conveyor for sale

The screw conveyor is of simple structure, low marking cost, strong sealing, safe ,convenient operation and other advantages, allowing multiple inlets and outlets. It is widely used in building materials, chemicals, electric power, metallurgy, coal, mine,food and other industries)to convey powder, granular and lump material, such as, coal, ash, slag, cement, food, etc.

Model: LSY165、LSY219、LSY273、LSY325

Capacity: 17-110t/h

Power: 3-22kw

Concrete screw conveyor is a mechanical equipment used to transport concrete and its raw materials (such as sand, stone, cement, etc.). It pushes the material to move axially through the rotation of the spiral blade, and is suitable for short-distance and medium-distance material transportation.

Concrete screw conveyor consists of the following main components:

Spiral blade: installed on the rotating shaft, it pushes the material along the conveying pipe by rotation.

Drive device: usually composed of a motor and a reducer, providing power to rotate the spiral shaft.

Conveying pipe: The spiral blade is installed in the conveying pipe, and the material is pushed forward by the spiral blade in the conveying pipe.

Feed port and discharge port: The material enters the conveyor from the feed port and is discharged from the discharge port.

advantages of Screw Conveyor

1.Made of high-quality steel, the steel has good integrity.

2.Double pitch blades reduce the pressure during material transportation.

3.Made of high-quality reducer, it has the characteristics of large torque and low noise.

4.Universal joint connection, more convenient installation.

5.The blade is integrally formed without clogging materials.

Parameters of Screw Conveyor

| Length (m) | LSY165 (17T/H) | LSY219 (49T/H) | LSY273 (80T/H) | LSY325 (110T/H) |

| <3 | 1000/5/3 | 2000/7/5.5 | 2000/7/7.5 | 3000/10/11 |

| <4 | 1000/5/3 | 2000/7/5.5 | 2000/7/7.5 | 3000/10/11 |

| <5 | 1000/5/3 | 2000/7/5.5 | 2000/7/7.5 | 3000/10/11 |

| <6 | 1000/5/3 | 2000/7/5.5 | 2000/7/11 | 3000/10/15 |

| <7 | 1000/5/4 | 2000/7/7.5 | 2000/7/11 | 3000/10/15 |

| <8 | 1000/5/4 | 2000/7/7.5 | 2000/7/11 | 3000/10/18.5 |

| <9 | 1000/5/4 | 2000/7/7.5 | 2000/7/11 | 3000/10/18.5 |

| <10 | 1000/5/5.5 | 2000/7/11 | 2000/7/15 | 3000/10/22 |

| <11 | 1000/5/5.5 | 2000/7/11 | 2000/7/15 | 3000/10/22 |

| <12 | 1000/5/5.5 | 2000/7/11 | 2000/7/15 | 3000/10/22 |

If the above parameters do not meet your production needs, you can contact us to let us know your specific requirements and we will design a unique solution and quotation for you.

Vertical cement silo for sale

The silo is combined by four main parts: the cover, wall sections, cone sand supporting legs. All parts are pressed by special machine and mould.especially the wall sections which can be changed every place on the wall Shipping in Container, installation on site.

Model: 50T、100T、200T、300T、500T、800T、1000T

Tank volume:50-1000T

Silo Diameter: 3.16-8M

Material storage: used to store bulk cement, fly ash, mineral powder and other powdered materials to provide a stable material supply.

Material transportation: the stored materials are transported to the mixer or other production equipment through equipment such as screw conveyors and air conveying chutes.

Metering control: equipped with weighing sensors and control systems to achieve accurate metering and control of materials and ensure the accuracy of production ratios.

When the bulk mud silo is working, it must be erected by a special crane and then placed on a prefabricated concrete foundation. The verticality of the cement silo with the horizontal plane must be checked after it is erected, and then its bottom must be firmly welded to the embedded parts of the foundation.

advantages of Vertical cement silo

1.Dust is discharged smoothly without sticking.

2.Dust collector, ensures dust-free outdoor and more beautiful environment.

3.Ladder and guardrail engineering, after installation, it is easy for workers to go to the top.

4.Support legs, the leg length of the silo can be customized according to requirements.

5.Top guardrail, ensure safety when workers are at the top.

6.It has a large storage capacity and can meet the needs of large-scale production.

7.The silo body has good sealing, which can effectively prevent the material from getting damp, agglomerating and contaminating.

8.Vertical design, small footprint, suitable for use in construction sites with limited space.

9.Simple structure, easy installation, and small maintenance workload.

Parameters of Vertical cement silo

| Cement Silo | Silo Diameter | Silo Body Height | Layers of silo body | Pieces each layer | Weight |

| 50T Cement Silo | 3160mm | 4260mm | 3 | 4 | 4.5T |

| 100T Cement Silo | 3160mm | 8700mm | 6 | 4 | 6T |

| 150T Cement Silo | 3160mm | 13000 mm | 9 | 4 | 9T |

| 200T Cement Silo | 4000mm | 11360 mm | 8 | 5 | 12T |

| 200T Cement Silo | 4500mm | 8700 mm | 6 | 6 | 12T |

| 300T Cement Silo | 5300mm | 8700 mm | 8 | 8 | 17T |

| 500T Cement Silo | 6800mm | 7300 mm | 8 | 8 | 21T |

| 600T Cement Silo | 6800mm | 8700 mm | 6 | 8 | 28T |

| 800T Cement Silo | 8000mm | 10100 mm | 7 | 10 | 43T |

| 1000T Cement Silo | 8000mm | 13200 mm | 9 | 10 | 56T |

If the above parameters do not meet your production needs, you can contact us to let us know your specific requirements and we will design a unique solution and quotation for you.

Horizontal cement silo for sale

Horizontal cement silo is a sealed silo for bulk materials, suitable for storing grain, cement, fly ash, powdered ore, dry mortar, etc. The cement silo is equipped with a level indicator to monitor the level and amount of material. The top is equipped with a dust filter and a safety valve to balance the internal and external pressure difference, making it easy to transport.

Model: 30T、50T、70T、100T

Tank volume:30-100T

Power: 18.5kw

Horizontal cement silo is a kind of equipment used to store bulk cement, fly ash, mineral powder and other powdered materials. Unlike vertical cement silo, horizontal cement silo adopts horizontal placement design, which is mainly used in occasions that need to be moved frequently or used in a small space. It is widely used in construction sites, concrete mixing plants, prefabricated component plants and other places.

Horizontal cement silo mainly consists of the following parts:

Bunker: usually cylindrical or rectangular structure, welded with steel plates, with good sealing and corrosion resistance.

Support structure: horizontal cement silo is usually supported by brackets or frames, and the bracket design enables it to be stably placed horizontally.

Dust removal device: used to remove dust in the silo, keep the silo clean, and prevent dust explosion.

Material level meter: used to detect the height of the material in the silo to ensure sufficient supply of materials.

Arch breaking device: used to prevent the material from arching in the silo to ensure the smooth flow of materials.

advantages of Horizontal cement silo

1.Easy to move: The horizontal design makes it more suitable for use in construction sites that require frequent movement.

2.Small footprint: The horizontal placement design makes it very suitable for use in limited space.

3.Good sealing: The silo has good sealing, which can effectively prevent the material from getting damp, agglomerating and contaminating.

4.Strong adaptability: Suitable for the storage and transportation of a variety of materials, including cement, fly ash, etc.

5.Convenient loading: Horizontal design, can be loaded into a 40HQ container.

6.Convenient installation: It can be installed on a flat concrete floor without the need for foundation engineering.

7.Free customization: The storage capacity can be freely customized according to actual needs.

Parameters of Horizontal cement silo

| Items | Horizontal Cement Silo | |||

| Tank Volume | 30 Ton | 50 Ton | 70 Ton | 100 Ton |

| Steel Material | Q235 Carbon Steel | Q235 Carbon Steel | Q235 Carbon Steel | Q235 Carbon Steel |

| Control System | Central Control | Central Control | Central Control | Central Control |

| Discharge Chute | 4 | 4 | 6 | 6 |

| Motor Power | 18.5kw | 18.5kw | 18.5kw | 18.5kw |

| Dimension Only Silo(mm) | 5800*2250*2550 | 7500*2250*2550 | 11500*2250*2550 | 9100X2250X4400 |

| Supporting Legs | 1500mm | 1500mm | 1500mm | 1500mm |

| Dust Filter | 1000mm | 1000mm | 1000mm | 1000mm |

| Flat Screw Conveyor | 219×5.8m | 219×7.5m | 273×11.5m | 273×9.1m |

| Pcs of Cross joints | 4 | 4 | 6 | 6 |

| Pcs of Vibrator | 4 | 4 | 6 | 6 |

| Pcs of Butterfly Valve | 4 | 4 | 6 | 6 |

If the above parameters do not meet your production needs, you can contact us to let us know your specific requirements and we will design a unique solution and quotation for you.

Application Areas

Concrete auxiliary equipment is an indispensable machine in concrete batching plant. The main purpose of these equipment is to improve production efficiency, ensure construction quality and ensure construction safety.

Spark concrete pump Price List

| Types | Price range |

| Aggregate batching machine | $2,000-$8,000 |

| Concrete screw conveyor | $8,000-$15,000 |

| Vertical cement silo | $3,000-$9,000 |

| Horizontal cement silo | $3500-$10,000 |

The price you pay depends on the line, machine and capacity you choose. The more equipment you choose and the greater the capacity, the higher the price you need to pay.

We also offer tailor-made solutions. If you are preparing a concrete batching plant, feel free to contact us for a customizable planning design and detailed price tag.