Spark Concrete Mixer

A concrete mixer is a mechanical equipment used to mix cement, sand and gravel aggregates and water into concrete. Due to its diverse mixing methods and structural types, it can meet the needs of projects of different scales and types and is widely used in various construction projects.

Our factory produces a wide variety of concrete mixers, common models include JS twin-shaft concrete mixer, JZC drum mixer, JZR drum mixer, planetary concrete mixer, and small drum concrete mixer.

Types of spark Concrete Mixer for sale

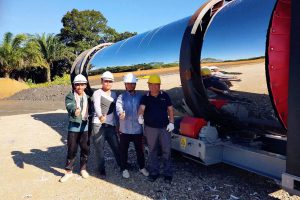

The concrete mixers produced by our factory can meet the needs of projects of different sizes and types. Because of their high efficiency, durability and easy maintenance, they can significantly improve construction efficiency and quality.

Application scenarios

High-rise buildings: Suitable for the vertical transportation needs of high-rise buildings, it can provide a stable supply of concrete to ensure the continuity and quality of construction.

Road and bridge construction: Suitable for long-distance transportation and large-scale concrete paving, it can quickly complete the concrete pouring of roads and bridges.

Tunnel and subway construction: The flexibility and maneuverability of the mixer make it suitable for the transportation and pouring of concrete in narrow spaces, and it is suitable for complex construction environments such as tunnels and subways.

Rural and small projects: The drum mixer is often used in rural self-mixing construction and small construction projects because of its small size and portability.

Water conservancy projects: The mixer can be used in the construction of concrete structures such as dams and levees to meet the high requirements of water conservancy projects for concrete quality and construction efficiency.

Industrial facilities: In the construction of industrial plants and warehouses, the mixer can improve construction efficiency and ensure the quality and supply of concrete.

What is a Concrete mixer ?

A concrete mixer is a mechanical device used to mix cement, sand, gravel, water and other materials into concrete in a certain proportion. It is widely used in various construction projects such as buildings, roads, bridges, tunnels, water conservancy projects, etc. It is one of the indispensable equipment in the concrete construction process.

Structural composition:

Mixing drum: The mixing drum is the core component of the concrete mixer, which is used to hold the materials to be mixed.

Mixing device: Mixing blades: Installed in the mixing drum, used to mix materials. Mixing shaft: The rotating shaft that supports the mixing blades, usually driven by a motor.

Transmission system: Motor and reducer: Provide power to drive the mixing shaft to rotate. The motor is usually used in conjunction with a reducer to adjust the mixing speed. Transmission device: Including gears, belts, etc., used to transmit the power of the motor to the mixing shaft.

Discharge system: Discharge door: Located at the bottom of the mixing drum, used to discharge the mixed concrete. The discharge door can be opened and closed by a cylinder, a hydraulic cylinder or manual operation.

Control system: The control system is used to control the opening and closing of the discharge door, usually including pneumatic or hydraulic control devices.

Mixing drum

Mixing blade

transmission device

Pneumatic device

The different aggregate will first put in the lifting hopper, then the lifting hopper will lift the aggregate to the mixer, at the same time, the water will be into mixer by the water pump, the water volume added is decide by the water flow,it’s adjustable, after the aggregate and water all in mixer, mixed 30-45 seconds, can discharging.

twin-shaft concrete mixer for sale

This series of mixers adopts a twin-shaft forced mixing design with two mixing shafts and multiple mixing blades. This design can achieve fast and uniform mixing, ensuring the quality and uniformity of concrete.

Model: JS500、JS750、JS1000、JS1500

Capacity: 25-90m³/h

Power: 18.5-44kw

JS series twin-shaft concrete mixer is a highly efficient and reliable concrete mixing equipment, which can mix dry hard concrete, plastic concrete, fluid concrete, lightweight aggregate concrete and various mortars, and is widely used in various construction projects and concrete mixing plants.

The concrete twin-shaft forced mixer is mainly composed of the casing, screw shaft assembly, drive device, piping, cover plate, chain cover and other parts. The casing is mainly composed of plates and steel, which are welded in the factory and assembled with other parts. It is the support of the twin-shaft mixer. The screw shaft assembly is the main component of the twin-shaft mixer, and its components mainly include left and right rotating screw shafts, bearing seats, bearing sleeves, bearing covers, gears, sprockets, oil cups, blades and other parts.

advantages of twin-shaft concrete mixer

1.High efficiency: The twin-shaft design improves mixing efficiency and production capacity.

2.Reliability: The use of high-quality materials and advanced technology ensures the reliability and stability of the equipment.

3.Environmental protection and energy saving: Energy saving and environmental protection are taken into consideration during the design, reducing noise and dust pollution.

4.Easy maintenance: The structural design facilitates maintenance and reduces downtime.

Parameters of twin-shaft concrete mixer

| Model | JS500 | JS500 | JS500 | JS500 |

| Feeding capacity | 800L | 1200L | 1500L | 1800L |

| Discharging capacity | 500L | 750L | 1000L | 1500L |

| Productivity | 25m³/h | 35m³/h | 50-60m³/h | 75-90m³/h |

| Mixer power | 18.5kw | 22kw | 2*18.5kw | 2*22kw |

| Aggregate large size | 60-80mm | 60-80mm | 60-80mm | 60-80mm |

| Work circle | 45-60s | 45-60s | 45-60s | 45-60s |

| Discharge height | 2-4.1m | 2-4.1m | 2-4.1m | 2-4.1m |

| Overall weight | 4000kg | 5500kg | 8700kg | 11300kg |

If the above parameters do not meet your production needs, you can contact us to let us know your specific requirements and we will design a unique solution and quotation for you.

drum concrete mixer for sale

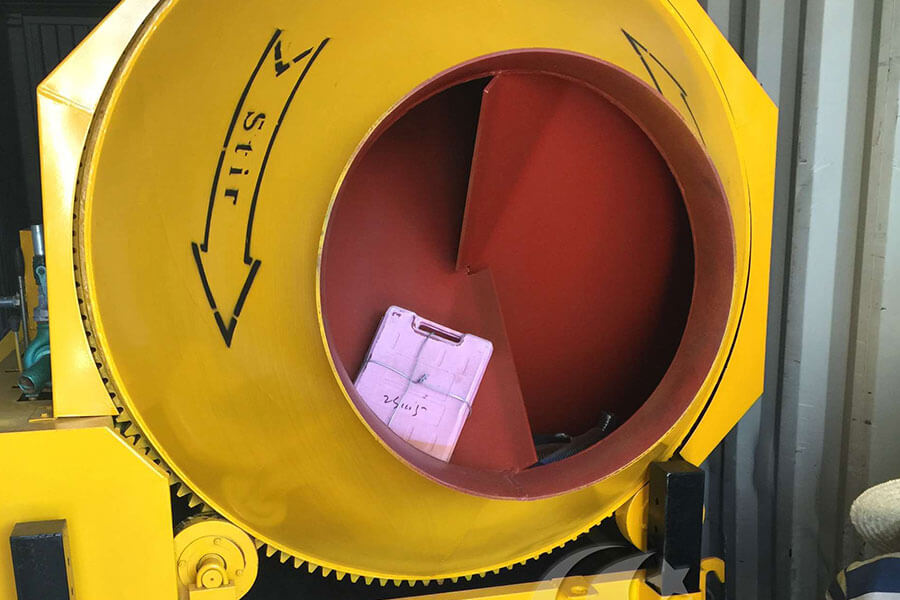

Drum concrete mixer is a common concrete mixing equipment. The mixing drum of the drum mixer is usually double-conical, with high and low blades installed inside. These blades form a certain angle with the axis of the drum to enhance the mixing effect. It is widely used in construction sites, road projects, bridge projects and small and medium-sized concrete component factories.

Model: JZC/JZR250、JZC/JZR350、JZC/JZR500、JZC/JZR750

Capacity: 6-30m³/h

Power: 4-15kw

The mixer drum is equipped with mixing blades. When the drum rotates, the blades lift the material to a certain height and then fall down by gravity. This self-falling mixing method achieves uniform mixing of materials through repeated lifting and falling of materials.

The drum concrete mixer is equipped with a rubber pad on the outer surface of the mixing drum, and a support wheel is installed on the driven shaft to rub against the rubber pad. At the same time, a spiral mixing blade is installed on the inner surface of the mixing drum.

The drum concrete mixers produced by our factory have various specifications and models. The common types can be divided into four types: JZC-A self-falling type, JZC-B self-falling type, JZR-A wire rope transmission, and JZR-B hydraulic transmission type.

The drum concrete mixers of the JZC-A series adopt the principle of self-falling mixing. They are usually equipped with double-conical mixing drums with high and low blades installed inside. These blades are at a certain angle to the axis of the drum to enhance the mixing effect.

The drum concrete mixers of the JZC-B series are optimized products of the JZC-A model. They adopt the principle of self-falling mixing and are optimized in some designs and performances to meet higher production efficiency and a wider range of application scenarios.

The JZR-A series adopts a wire rope transmission system. The mixing drum is connected to the drive device through a wire rope, and the tension of the wire rope ensures the smooth rotation of the mixing drum. This transmission method has the characteristics of simple structure and convenient maintenance

The JZR-B series adopts a hydraulic transmission system. The mixing drum is driven by a hydraulic device, and the whole machine runs stably and efficiently. This transmission method has the characteristics of stability and efficiency.

advantages of drum concrete mixer

1.Simple structure: compact design, simple structure, easy to install and maintain.

2.Strong mobility: usually mobile design, easy to transfer between different construction sites.

3.High mixing efficiency: self-falling mixing can effectively improve mixing efficiency and uniformity of concrete.

4.Strong durability: made of wear-resistant materials, can effectively resist the wear and corrosion of concrete.

5.Easy maintenance: the transmission system is simple in design and easy to maintain, which can effectively reduce the failure rate and downtime.

6.Easy operation: simple operation and maintenance, suitable for all kinds of operators.

Parameters of drum concrete mixer

| Item\Model | JZC/JZR250 | JZC/JZR350 | JZC/JZR500 | JZC/JZR750 |

| Feeding capacity(L) | 320 | 560 | 800 | 1200 |

| Discharging capacity(L) | 250L | 350L | 500L | 750L |

| Productivity(M3/H) | 6-8 | 10-14 | 18-20 | 25-30 |

| Roatating speed of stirring shaft(r/min) | 17 | 14 | 13 | 13 |

| Max.diameter of aggregates(mm) | 60 | 60 | 80 | 80 |

| Mixer motor(kw) | 4 | 5.5 | 11 | 15 |

| Lift motor(kw) | 4 | 4.5 | 5.5 | 7.5 |

| Water pump(kw) | 0.55 | 0.55 | 0.75 | 1.1 |

| Tyre standard | 6.50-16 | 6.50-16 | 7.50-16 | 7.50-16 |

| Max.transport speed(Km/h) | 20 | 20 | 20 | 20 |

| Weight(kg) | 1800 | 1950 | 3100 | 4200 |

If the above parameters do not meet your production needs, you can contact us to let us know your specific requirements and we will design a unique solution and quotation for you.

Planetary concrete mixer for sale

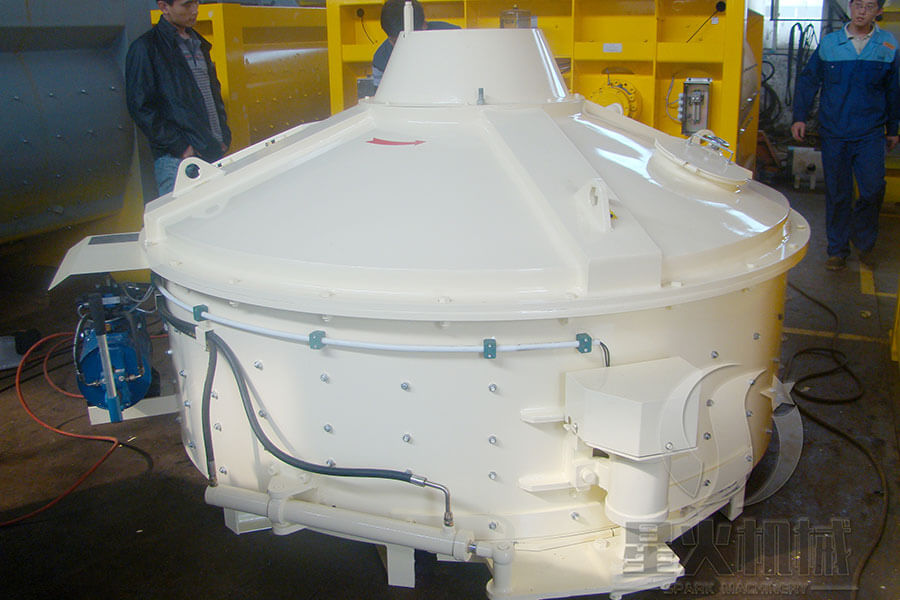

The planetary concrete mixer is an advanced mixing equipment. The mixing arm not only revolves around the central axis of the mixing drum, but also rotates on its own. This compound movement ensures that the mixing blades can cover every corner of the mixing drum to achieve all-round material mixing.

Model: MP500、MP750、MP1000、MP1250、MP1500、MP2000

Feeding capacity:75-3000L

Power: 18.5-75kw

The design of the planetary mixer is inspired by the principle of planetary motion. It has unique technical features and significant application advantages. Due to the complex and comprehensive movement trajectory of the mixing arm, the planetary mixer can quickly break the agglomeration between material particles and promote the formation of various components. Fully integrated to improve the homogeneity and strength of concrete.

Suitable for various types of concrete, including ordinary concrete, high-performance concrete and concrete with special requirements. It can adapt to different mixing needs by adjusting the mixing parameters and replacing the mixing blades, and is widely used in construction, industry, chemical industry and other fields.

advantages of Planetary concrete mixer

1. High-quality mixing: ensure the uniform distribution of concrete components, effectively avoid segregation and stratification, and improve the strength and durability of concrete.

2. Efficient production: The efficient mixing capacity enables it to complete the mixing task of a large amount of concrete in a shorter time, meeting the time node requirements of large-scale projects.

3. Energy saving and environmental protection: less energy loss, good sealing performance, reduced dust and noise pollution, in line with the concept of modern green construction.

4. High-strength wear-resistant materials: The mixing drum is usually made of high-strength wear-resistant materials to ensure excellent durability under long-term high-intensity work.

5. Low noise and high efficiency: The planetary gear reducer design is adopted, with low noise and high mechanical efficiency, which can effectively save power use and reduce equipment space.

Parameters of Planetary concrete mixer

| Model | MP500 | MP750 | MP1000 | MP1250 | MP1500 | MP2000 |

| Feeding capacity | 750L | 1125L | 1500L | 1875L | 2250L | 3000L |

| Discharging | 500L | 750L | 1000L | 1250L | 1500L | 2000L |

| Overall weight | 1800kg | 2400kg | 3000kg | 3600kg | 4800kg | 6000kg |

| Mixer power | 18.5kw | 30kw | 37kw | 45kw | 55kw | 75kw |

| Discharge power | 2.2kw | 2.2kw | 3kw | 3kw | 3kw | 4kw |

| Planet/main planet | 1/2nr | 1/3nr | 2/4nr | 2/4nr | 2/4nr | 3/6nr |

| Paddle | 1 | 1 | 1 | 1 | 1 | 1 |

| Discharging paddle | 1 | 1 | 1 | 1 | 2 | 2 |

| Lifting power | 4kw | 7.5kw | 11kw | 15kw | 15kw | 22kw |

If the above parameters do not meet your production needs, you can contact us to let us know your specific requirements and we will design a unique solution and quotation for you.

Small drum concrete mixer for sale

This small hand concrete mixer can be used for mixing plastic and semi-dry concrete. The mixing drum rotates forward to stir and reverse to discharge, and it can produce 4 to 5 cubic meters per hour. It is suitable for construction sites, roads, bridge projects and small and medium-sized concrete component factories without electricity.

Model: CM260、CM300、CM350、CM400、CM450、CM500、CM600

Capacity: 6-20m³/h

Power: 1.5-3kw

This small drum concrete mixer can manually add materials and water to the concrete mixer, and then use the wheel to rotate the concrete mixer drum to ensure that the concrete is completed, and then manually unload. The whole set of equipment is composed of a drum, a control wheel, and a moving wheel.

This machine is an exclusive drum concrete mixer manufactured by us for customers with small projects. It occupies a small area and can mix 1-5 bags of cement at a time. It is suitable for personal or family use.

advantages of Small drum concrete mixer

1.The drum mixer has novel structure and beautiful appearance.

2.High production efficiency, good mixing quality and light weight.

3.Type of gasoline/diesel drum mixer.

4.Easy to move, simple to operate and small size.

Parameters of Small drum concrete mixer

| Model | CM260 | CM300 | CM350 | CM400 | CM450L | CM500 | CM600 |

| Feed Capacity | 260L | 300L | 350L | 400L | 450L | 500L | 600L |

| Drum Mouth | 450mm | 450mm | 516mm | 516mm | 516mm | 566mm | 566mm |

| Drum Diameter | 750mm | 750mm | 800mm | 800mm | 800mm | 900mm | 900mm |

| Drum Height | 687mm | 777mm | 777mm | 850mm | 936mm | 936mm | 1040mm |

| RPM of Drum | 18 | 20 | 20 | 20 | 20 | 17 | 17 |

| Drum thickness | 4mm | 4mm | 4mm | 4mm | 4mm | 4mm | 4mm |

| Productivity | 6m³/h | 8m³/h | 10m³/h | 12m³/h | 14m³/h | 16m³/h | 20m³/h |

| Ring Gear | Cast Iron | Cast Iron | Cast Iron | Cast Iron | Cast Iron | Cast Iron | Cast Iron |

| Diesel engine | 6HP | 6HP | 6HP | 6HP | 6HP | 9HP | 9HP |

| Gasoline engine | 5.5HP | 5.5HP | 6.5HP | 6.5HP | 6.5HP | 9HP | 9HP |

| Electric motor | 1.5kw | 1.5kw | 2.2kw | 2.2kw | 2.2kw | 3kw | 3kw |

| Handle type | Swivel handle | ||||||

| Wheel | pneumatic wheel | ||||||

If the above parameters do not meet your production needs, you can contact us to let us know your specific requirements and we will design a unique solution and quotation for you.

Application Areas

Concrete mixers are widely used in many fields such as building construction and infrastructure construction: construction sites, residential and commercial buildings, infrastructure construction, bridge projects, road construction, prefabricated component plants and various types of construction projects.

Spark concrete pump Price List

| Types | Price range |

| Twin-shaft concrete mixer | $5,000-$20,000 |

| Drum concrete mixer | $5,000-$15,000 |

| Planetary concrete mixer | $20,000-$50,000 |

| Small drum concrete mixer | $800-$10,000 |

The price you pay depends on the line, machine and capacity you choose. The more equipment you choose and the greater the capacity, the higher the price you need to pay.

We also offer tailor-made solutions. If you are preparing a concrete mixer, feel free to contact us for a customizable planning design and detailed price tag.